Newly Arrival Multi Collagen Makeover - Factory Collagen Peptide marine fish collagen peptide raw powder for food beverages – Taiai Peptide

Newly Arrival Multi Collagen Makeover - Factory Collagen Peptide marine fish collagen peptide raw powder for food beverages – Taiai Peptide Detail:

Marine cod collagen peptide powder is made from deep-sea cod fish skin as raw material, and through enzymatic hydrolysis technology, Fish Skin Collagen 500MT per year, including food grade and cosmetic Grade. Because of good raw materials, advanced technology and strict QC system, Fish collagen produced by Reddon is of very high quality. Cod peptides have excellent affinity with human skin, can well exert its functions such as penetration and repair, and can comprehensively improve skin quality. It is a high-level “health cosmetic” favored by women.

Enhance immunity: Collagen peptides can significantly enhance the cellular and humoral immunity of the human body.

Antioxidation, anti-wrinkle and anti-aging.

Moisturizing and moisturizing: Contains a variety of amino acid components, has a large number of hydrophilic groups, and has a good moisturizing effect. Collagen peptides can promote the synthesis of skin collagen, maintain skin elasticity, make skin delicate and shiny, improve skin, and increase moisture.

It can enhance the function of osteoblasts, prevent osteoporosis, enhance calcium absorption, and increase bone density.

Material Source: Marine cod skin

Color: White or light yellow

State: Powder

Technology: Enzymatic hydrolysis

Smell: Slightly fishy

Molecular Weight: 300-500Dal

Protein: ≥ 90%

Product Features: Purity, non additive, pure collagen protein peptide

Package: 1KG/Bag, or customized.

Peptide is composed of 2-9 amino acids.

Liquid food: milk, yogurt, juice drinks, sports drinks and soy milk, etc.

Alcoholic beverages: liquor, wine and fruit wine, beer, etc.

Solid food: milk powder, protein powder, infant formula, bakery and meat products, etc.

Health food: health functional nutritional powder, pill, tablet, capsule, oral liquid.

Feed veterinary medicine: animal feed, nutritional feed, aquatic feed, vitamin feed, etc.

Daily chemical products: facial cleanser, beauty cream, lotion, shampoo, toothpaste, shower gel, facial mask, etc.

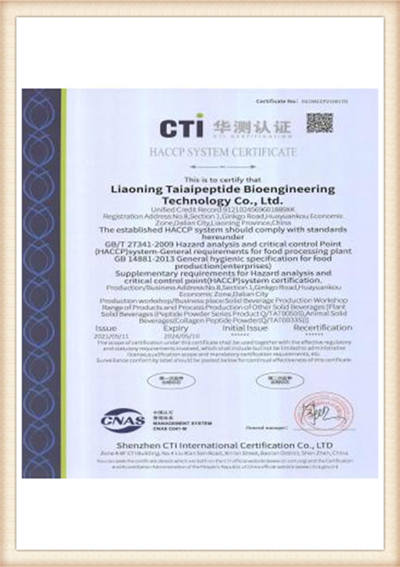

Haccp ISO9001 FDA

24 years R&D experience, 20 productions lines. 5000 ton peptide for every year,10000 square R&D building, 50 R&D team. Over 200 bioactive peptide extraction and mass production technology.

Production Line

Advanced production equipment and technology. The production line consists of cleaning, enzymatic hydrolysis, filtration concentration, spray drying, etc. The conveying of materials throughout the production process is automated. Easy to clean and disinfect.

Product Quality Management

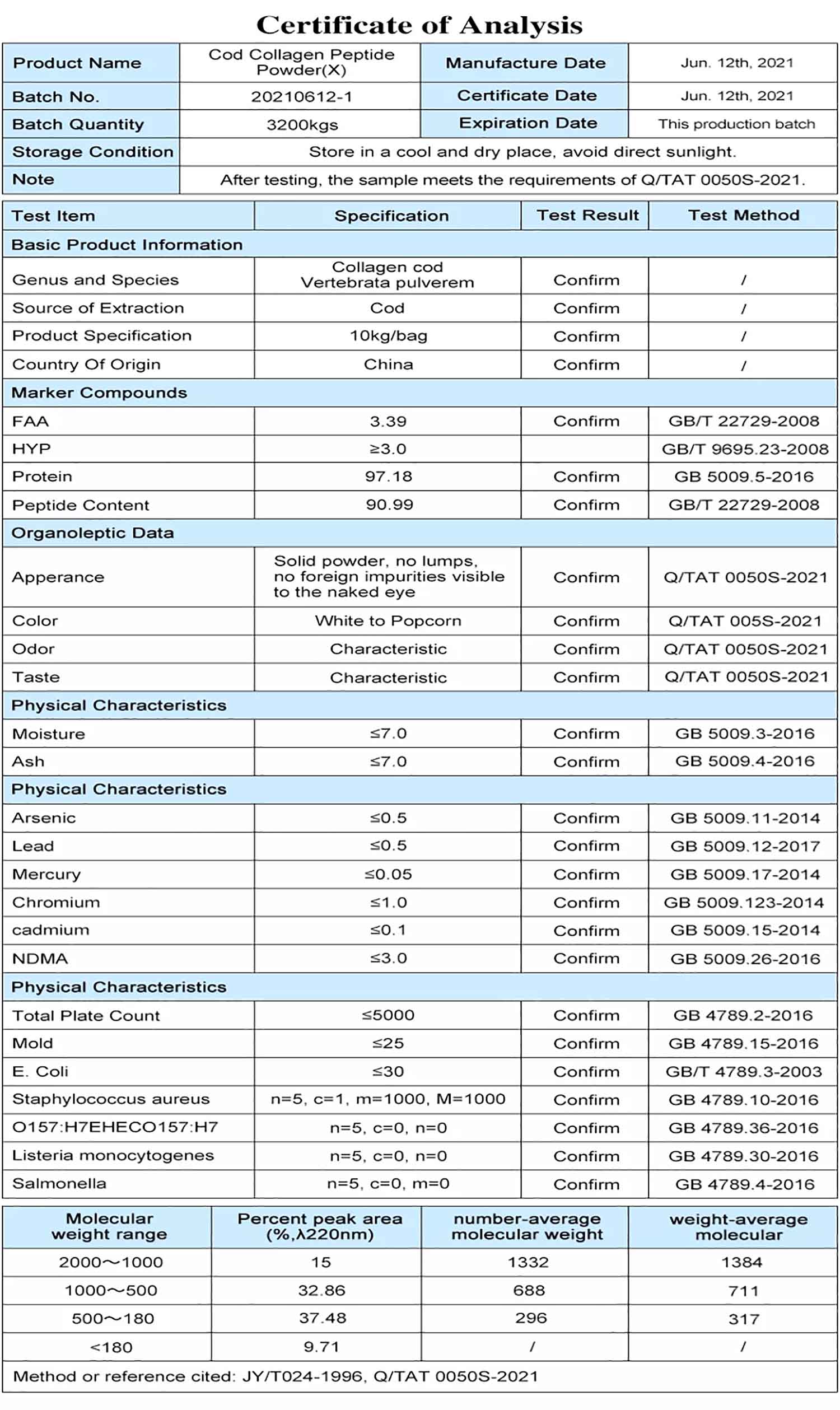

The laboratory covers an area of 2,000 square meters and is divided into several functional areas such as microbiology room, physical and chemical room, weighing room, and high temperature room. Equipped with high-performance liquid analyzer, atomic absorption fat analyzer and other precision instruments. Establish and improve the quality management system, passed the certification of FDA, HACCP, FSSC22000, ISO22000, IS09001 and other systems.

Production management

The production management department is composed of the production department and the workshop, and undertakes production orders, raw material procurement, warehousing, feeding, production, packaging, inspection and warehousing professional production processes.

Payment Terms

L/C T/T Western Union.

Package & Shipping

Length:47cm Weight: 27cm High: 8cm Weight: 1.45kg or 10kg box.

Product detail pictures:

Related Product Guide:

"Control the quality by the details, show the strength by quality". Our company has strived to establish a highly efficient and stable staff team and explored an effective quality control process for Newly Arrival Multi Collagen Makeover - Factory Collagen Peptide marine fish collagen peptide raw powder for food beverages – Taiai Peptide , The product will supply to all over the world, such as: Seattle, Israel, Nicaragua, We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.